CKE 6150

Flat Bed CNC Lathe

CNC Lathe Machine

Main features:

CKE6150i CNC Lathe Machine – Precision and Productivity Combined

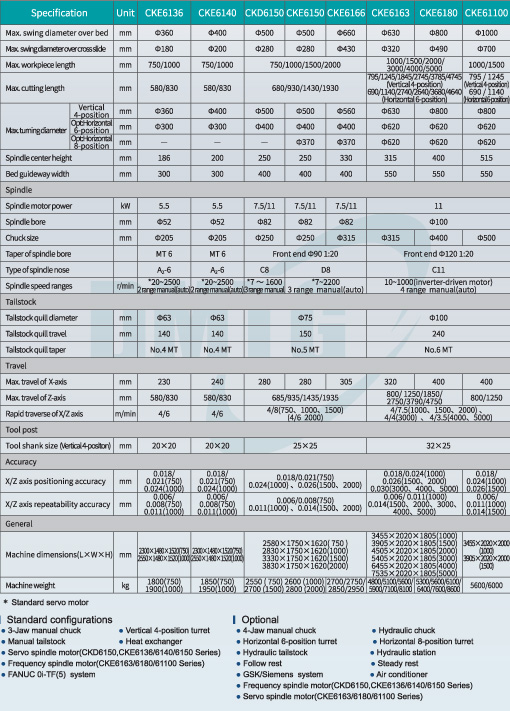

The CKE6150i CNC Lathe is a robust and high-precision turning solution designed for machining small to medium-sized parts with speed and accuracy. Featuring a swing over bed of 500mm and turning length up to 1000mm, it is ideal for a wide range of applications including automotive, aerospace, toolmaking, and general metalworking.

Its CNC control system supports intuitive programming, fast setup, and flexible operation—from single-piece jobs to batch production. The servo-driven axis system, combined with a rigid cast iron body and powerful spindle motor, ensures stability and consistent machining accuracy.

Equipped with a 4-station or optional multi-station electric turret, auto lubrication system, and optional accessories like hydraulic chuck or tailstock, the CKE6150i is designed to streamline production and reduce downtime.

Reliable, efficient, and easy to operate, the CKE6150i is a smart investment for workshops seeking dependable CNC lathe performance.

- The main elements, including the bed, headstock, saddle, and plinth, are composed of high-quality, durable castings.

- Mating surfaces between the saddle and guideways are coated with low-friction Turcite-B for smoother operations.

- The use of precision ball screws and rigid precision bearings enhances accurate positioning and facilitates heavy-duty cutting.

- A centralized oil system ensures automatic, forced lubrication onto ball screws and all other mating surfaces.

- Two model ranges are available:

- The CKE-Z series boasts automatic headstock gear changing, a wide range of high spindle speeds, and maintains noise levels below 80db.

- The CKE-I series features an independent spindle structure with a frequency-converted spindle motor or servo motor, providing stepless, high spindle speeds.

- The control panel is operator-adjustable, supporting traditional tool settings.

- Full enclosure guards with interlocks create a waterproof and chip-free workspace.

- A horizontal 4-P automatic indexing toolpost is standard, with options for vertical 4-P toolpost, horizontal 6-P toolpost, quick-change toolpost, and more to meet customers’ specific needs.

- Optional equipment includes a pneumatic or hydraulic chuck and tailstock.

- Control systems can be provided by FANUC, SIEMENS, FAGOR, etc. The E-handwheel function is also available.