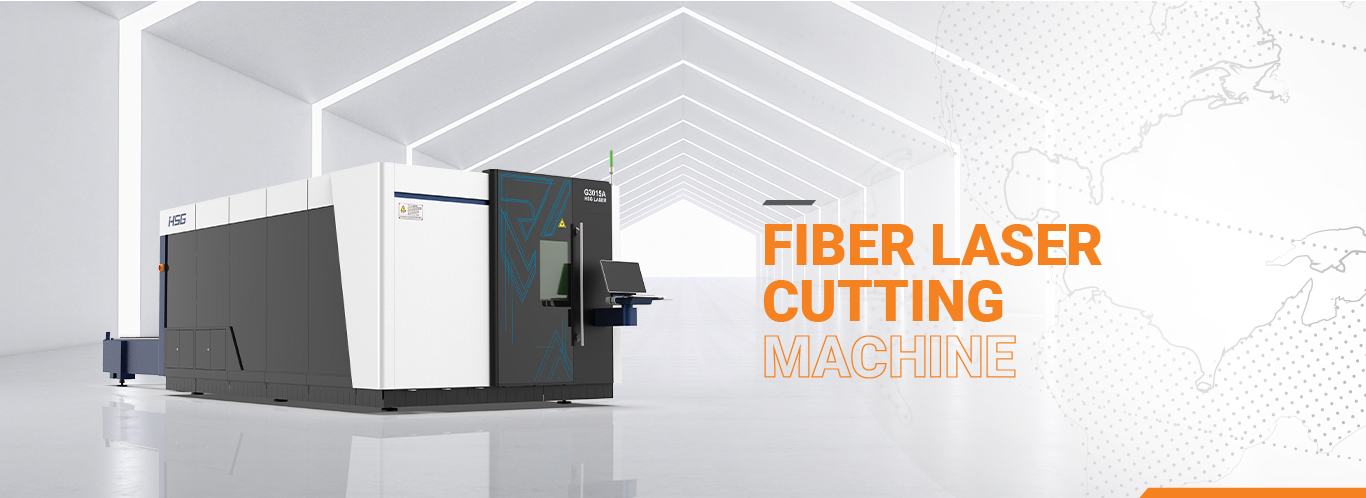

FIBER LASER CUTTING MACHINE SUPPLIER MALAYSIA

The Leading CNC Laser Cutting Machine in the Industry

As a fiber laser cutting machine supplier in Malaysia, our company prides itself on supplying high-quality industrial machinery and reliable products that meet the needs of our clients. With advanced technology and skilled workers, we are able to provide precision cutting machines, from metal to aluminium. Our commitment to customer satisfaction means that we work closely with our clients to understand their specific needs and deliver tailored sheet cutting machine solutions that help them achieve their goals. With our expertise and experience, we aim to be a trusted partner for businesses looking for reliable and efficient laser cutting machine equipment.

The Fiber Laser Cutting Machine that we offer is built for long-life with precision components.

Besides, its rigid construction is able to work continuously and precisely in the most severe condition. Apart from that, CNC Laser Cutting Machine can cut and process many materials.

In addition, excellent in speed and perfect cut on sheets of metal. In consequence, you can find several options that can serve most industrial needs.

Then, whether you’re working with stainless steel, mild steel or aluminum, fiber laser cutting machine can provide the optimum result for you.

Advantages Of Fiber Laser Cutting Machine

- High precision cutting: Achieve unparalleled precision with laser cutting, ensuring flawless cuts and intricate designs.

- Versatility: Cut through various materials, including metals, plastics, and composites, making laser cutting machines suitable for diverse industrial applications.

- Minimal maintenance: Experience minimal downtime and lower maintenance costs with simplified design and fewer moving parts of fiber laser cutting machines.

- Energy-efficient: Save on energy costs and reduce environmental impact with the energy-efficient operation

- Faster cutting speeds: Boost productivity with the high-speed performance, reducing production cycles and maximizing throughput.

Applications of Laser Cutting Machine:

Electronics Manufacturing:

- Metal casings

- Heat sinks

- Component mounts

Automotive Industry:

- Car chassis parts

- Brackets

- Engine mounts

Construction and Architecture:

- Structural frames

- Decorative panels or grills

- Railings

Machinery and Equipment Manufacturing:

- Machine parts

- Enclosures

- Mounting plates

Promotional Items and Branding:

- Metallic plaques

- Branded signage

- Event tokens or medallions

Furniture and Decor:

- Metal furniture frames

- Decorative wall art

- Lampshades

Agriculture and Farming Equipment:

- Equipment parts

- Protective grills

- Tool components

Laser Cutting Machine Flexible for Tube and Plate

Our expertise in laser cutting technology allows us to offer exceptional flexibility when it comes to cutting materials in both plate or flat sheet and tube forms. This versatility allows fabricators to cater to a wide range of applications.

When it comes to flat sheets, laser cutting machines can intricately carve out intricate shapes, patterns, or even simple straight cuts with precision. On the other hand, for tubes, lasers enable the creation of complex cuts and designs, making it ideal for applications like automotive exhaust systems, architectural components, and even medical instruments.

We understand the diverse needs of our clients, and our state-of-the-art laser cutting equipment enables us to cater to a wide range of applications with precision and accuracy. Whether it’s intricate patterns and designs on flat sheets or complex cuts in tubes, we have the capabilities to deliver high-quality results that meet the most demanding specifications.

Choose your most compatible laser cutting machine with us, whether in Selangor, Johor or Penang, we are ready to give the best for you.

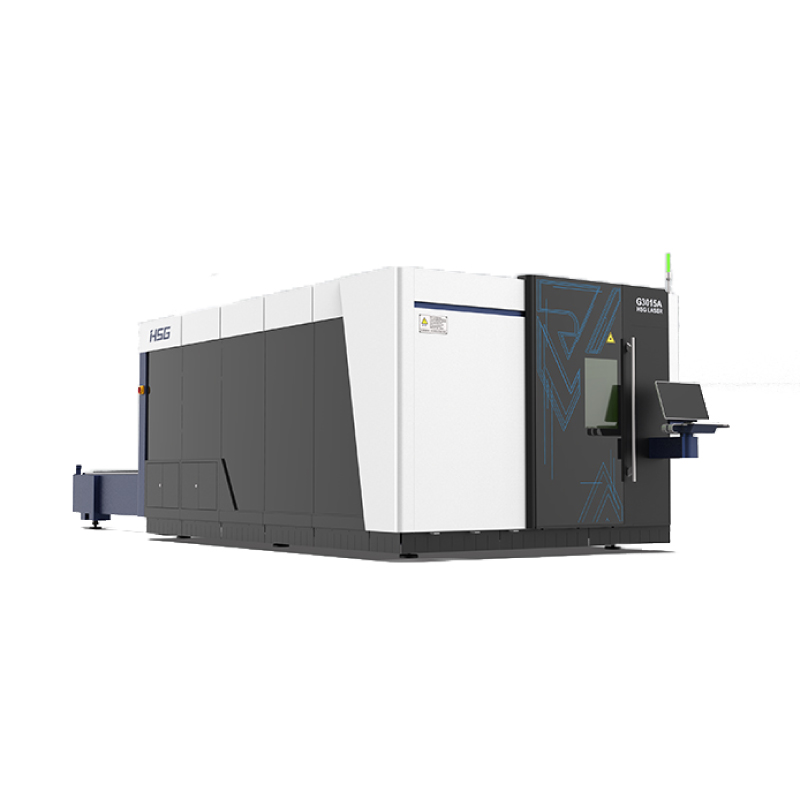

Browse Our Laser Cutting Machines

Product Specification: HS-G3015X(Plate)

| Technical Parameter | G3015X |

|---|---|

| Processing Format (L*W) | 3048*1524mm |

| Power | 2000-6000W |

| X/Y-axis Positioning Accuracy | ±0.03mm/m |

| X/Y-axis Repositioning Accuracy | ±0.03mm/m |

| Max. Acceleration | 1.5G |

| Max. No-load Speed | 140m/min |

| Max. Loading Weight | 900KG |

| Overseas Transport | One 40HQ Standard Container |

| Overall Dimensions (L*W*H) | 8900*2260*2200mm |

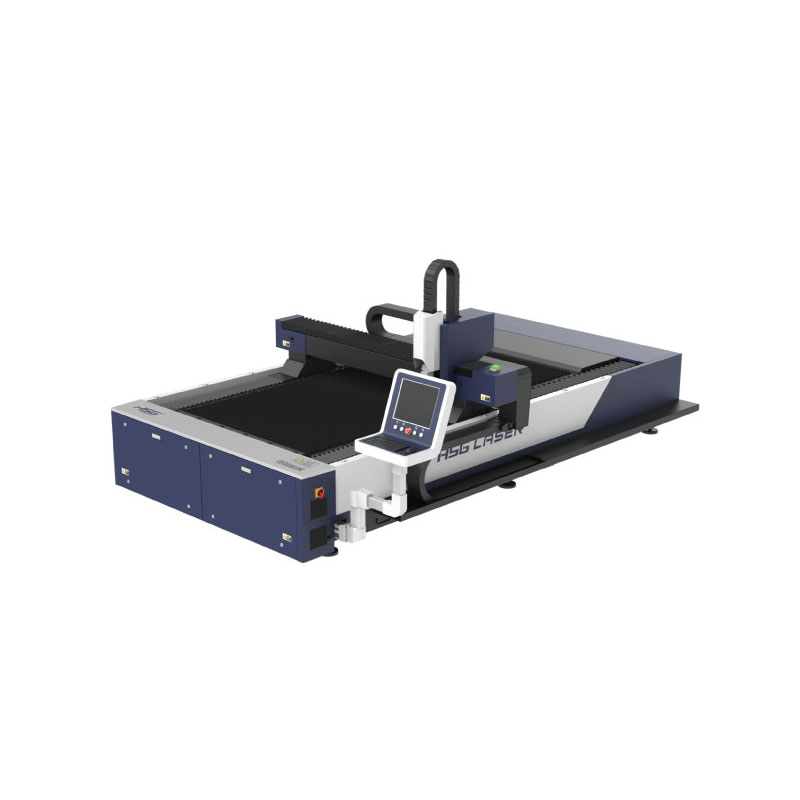

Product Specification: HS-G3015C(Plate)

| Feature/Model | G3015C | G4015C | G4020C |

|---|---|---|---|

| Working Area (L*W) | 3000mm*1500mm | 4000mm*1500mm | 4000mm*2000mm |

| Stroke (X/Y/Z Axis) | 1525mm/3025mm/150mm | 1525mm/4025mm/150mm | 2025mm/4025mm/150mm |

| X/Y-axis Positioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| X/Y-axis Repositioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Max. Moving Speed | 100m/min | 100m/min | 100m/min |

| Max. Acc. Speed | 1.0G | 1.0G | 1.0G |

| Power Porection Grade | IP54 | IP54 | IP54 |

| Laser Power | 1500W~4000W | 1500W~4000W | 1500W~4000W |

| Max. Loading Weight | 800KG | 1000KG | 1400KG |

| Overall Dimensions (L*W*H) | 4850*2730*1700mm | 6015*2730*1700mm | 6015*3300*1700mm |

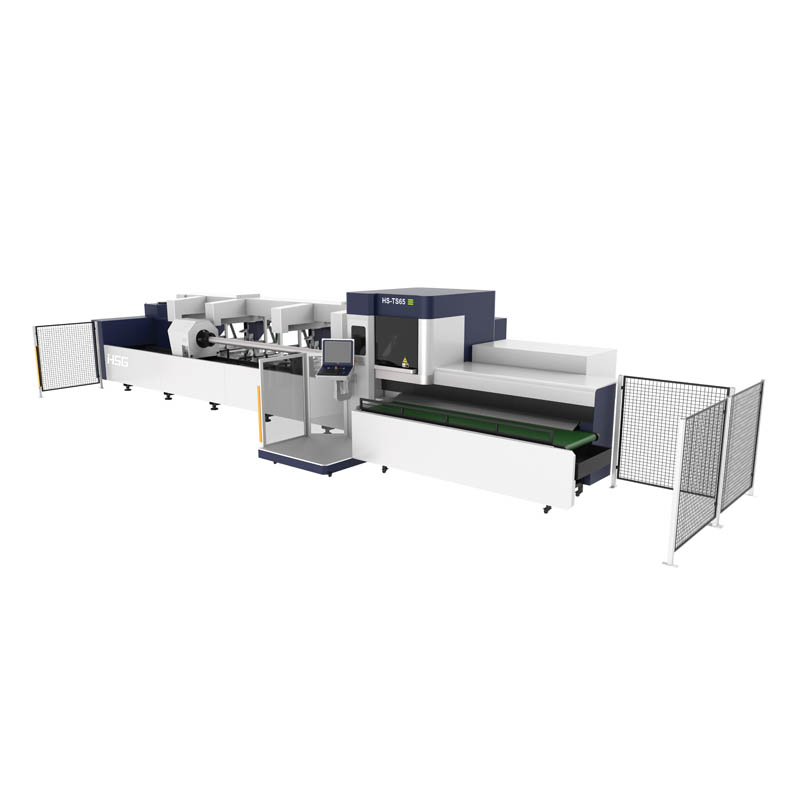

Product Specification: HS-TS65(Tube)

| Tube Diameter | Laser Power | Max. Moving Speed | Max. Acc. Speed |

|---|---|---|---|

| Φ12-Φ254mm | 1000W-4000W | 120m/min | 1.2G |

| Positioning Accuracy | Repositioning Accuracy | Machine Weight | Overall Dimensions |

| ±0.03mm/m | ±0.03mm | 12000Kg | 12000*3500*2800mm |

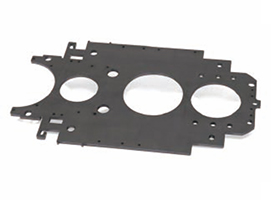

Cutting Samples

Videos Gallery

HSG HS-G4020H 12000W Laser Cutting Machine Demonstration

Single Table Steel Plate by Fiber Laser Cutting Machine

Test Cut Demo by Fiber Laser Cutting Machine

HSG HS-G4020H 12000W Laser Cutting Machine Demonstration

Single Table Steel Plate by Fiber Laser Cutting Machine

Test Cut Demo by Fiber Laser Cutting Machine

Frequently Asked Questions (FAQs)

How do I choose a laser cutting machine for my fabrication job?

Selecting the right laser cutting machine for your fabrication job involves understanding your project requirements. Consider factors such as material type, thickness, and the complexity of the cuts. A high-wattage machine may be necessary for thicker, denser materials, while a lower wattage machine may suffice for finer, more detailed work. Evaluate the machine’s cutting speed, precision, compatibility with CAD or CAM software, and after-sales service. It’s also beneficial to consult with manufacturers and read reviews to make an informed decision.

How thick can a 6000-watt laser cutting machine cut?

A 6000-watt laser cutting machine is a powerful tool capable of cutting through significant thicknesses. For metals like steel, such machines can typically cut around 1 inch (25 mm), depending on the metal’s grade and the machine’s brand and model. For example, a 6kW industrial laser cutter has the capacity to efficiently cut through mild steel up to 22mm thick and stainless steel up to 16mm thick.

So, it’s essential to consult with a specific machinery seller in Malaysia to get precise cutting capabilities as they can vary based on laser machine technology and recommending customer the right laser power.

How thick will a 3000-watt laser cutting machine cut?

A 3000-watt laser cutter is a versatile machine suitable for various applications. It can generally cut steel up to 0.4 to 0.6 inches (10-15 mm) thick, but this may differ based on the material and the machine’s specifics. As an illustration, the cutting prowess of a 3kW laser cutter is evident in its ability to seamlessly cut mild steel up to 16mm and stainless steel up to 8mm in thickness.

For accurate information, checking with our local laser equipment/machinery provider is recommended, as they can give detailed insights into the machine’s performance on different materials.

What is the average laser cutting machine Malaysia price?

The price of laser cutting machine in Malaysia varies widely based on factors such as wattage, brand, model, table size, power and the machine’s capabilities and add-ons. Entry-level laser cutting machine can be quite affordable nowadays in the Malaysia market, while higher power laser cutting machine or the one with bevel cutting can go up into the hundreds of thousands. To get a more specific price range, it’s advisable to get quotes from Hasil Karya Sdn Bhd and compare against the features and services we offer.

How often should a laser cutter be serviced?

Regular servicing is crucial for the longevity and optimal performance of a laser cutter. Most manufacturers recommend a maintenance check at least once a year, but this can vary based on the machine’s usage frequency. High-use environments may require more frequent servicing, such as bi-annually or quarterly, to maintain accuracy and efficiency.

One of the primary advantages of laser cutter is that it requires no maintenance.

How much does it cost to run a laser cutting machine?

The cost to run a laser cutting machine encompasses electricity consumption, replacement parts like lenses and nozzles, and occasional servicing are not high. It mainly depends on the power of the machine. Up to date, fiber laser is the most efficient machine in cutting because of its maintenance free, low consumables and high efficiency.

For a precise cost breakdown, consider the power usage in kilowatts per hour of the laser, the local cost of electricity, consumables, and any scheduled maintenance plans.

You have questions? We have the answers.

Reach out to us if you need more information about FIBER LASER CUTTING MACHINE. We are happy to serve you.