LATHE MACHINE

CNC Lathes Machine that Maximizes Efficiency

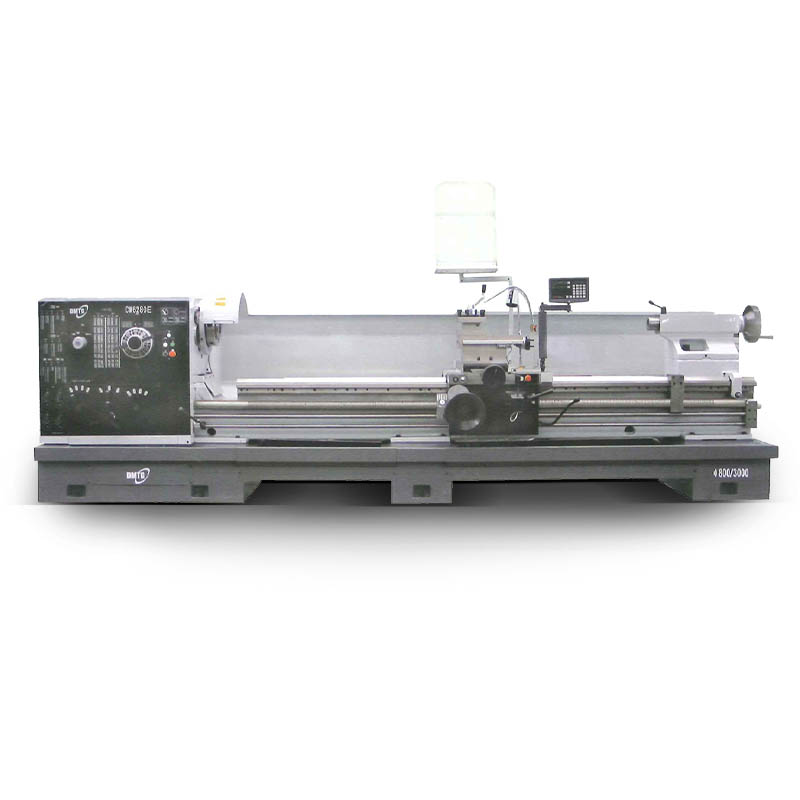

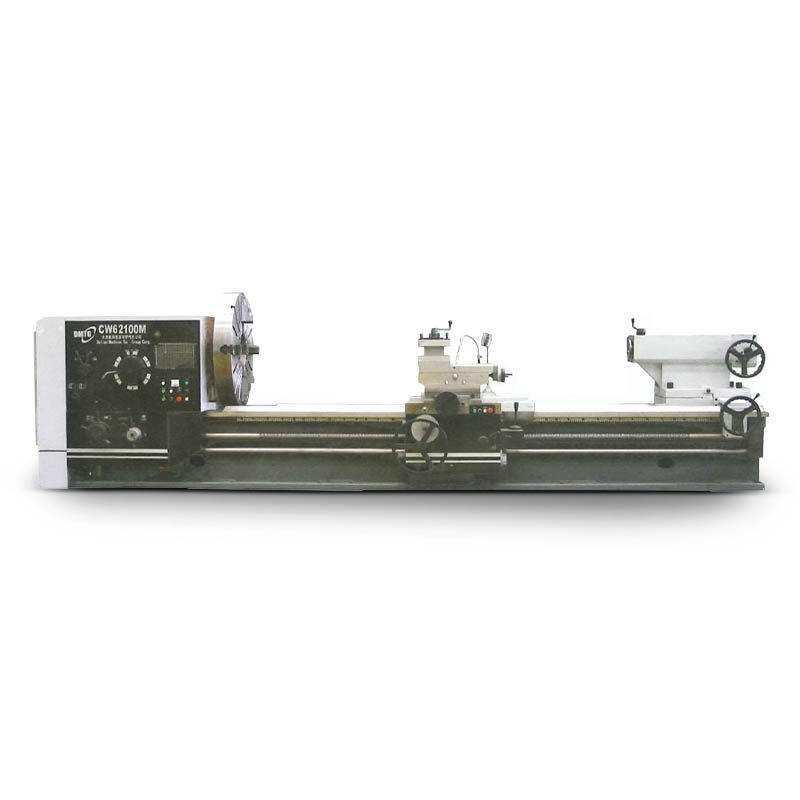

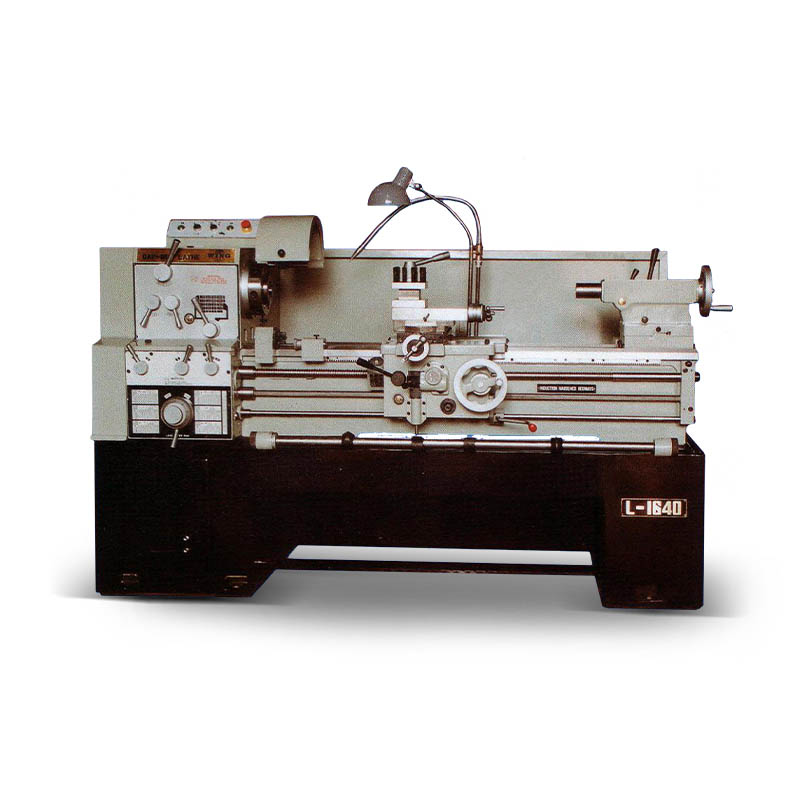

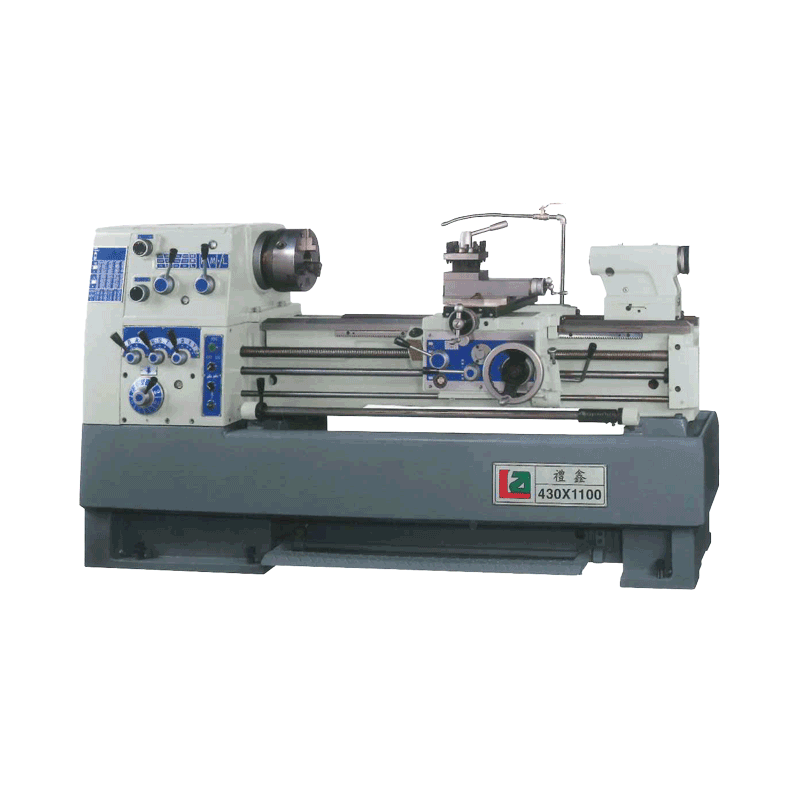

Hasil Karya’s broad range of CNC Lathes Machine and Lathe Machine offers a variety of bore sizes, bed lengths, and optional features. Thus, because of this variety allows us to create custom lathe solutions capable to meet any production needs.

In addition, our CNC Lathe Machine features compact and reasonable design. Due to electromechanical integration and the overall compact layout. Therefore, making it easy for repair and maintenance. Also, high efficiency, high precision, and high rigidity in process.

Besides, ensuring a machine’s longevity goes beyond the point of sale. As one of the leading lathe machine supplier in Malaysia, Hasil Karya provide post-sale service for our cnc lathe and metal lathe, offering comprehensive warranties, routine maintenance, and quick response times to service requests. This unwavering support makes us the ideal partner for businesses, promising seamless operations long after the machine’s installation.

Also, we catered this post-sale service throughout Malaysia apart from Selangor, Johor and Penang.

Even with outstanding quality and post-sale service, competitive pricing remains a key factor in choosing a supplier. We understand this delicate balance, offering competitively priced CNC turning and lathe machines without compromising on quality or support.

In today’s world, businesses are looking beyond just profit. Many seek partners who share their commitment to sustainability. Being one of the leading lathe machine and CNC turning machine supplier, Hasil Karya rise to this challenge, ensuring their processes are environmentally friendly, from production right through to disposal.

Browse Our CNC Lathe Machine

Cutting Sample

Videos Gallery

Frequently Asked Questions (FAQs)

What is a CNC lathe machine?

A CNC lathe is a machine used in metalworking for precise machining tasks that is controlled by Computer Numerical Control (CNC).

What are the key safety features in a CNC lathe machine to look for?

Emergency stop buttons, safety guards, and overload protection are crucial.

What should I look for in a CNC Turning Machine?

Consider material compatibility, workpiece dimensions, and your skill level, among other things.

What are the different parts of a CNC Lathe Machine?

A CNC lathe is a complex machine with many different components. Here are some of the most important parts:

Bed: The bed is the base of the machine, and it supports all of the other components.

Headstock: A sturdy headstock cradles the spinning spindle, the lifeblood of the CNC lathe, which is the rotating shaft that holds the workpiece.

Spindle: The spindle is the heart of the CNC lathe, and it spins the workpiece at high speeds.

Tailstock: The tailstock provides support for the workpiece on the other end of the spindle.

What can you use a CNC Lathe For?

CNC lathes are used to create a wide variety of parts, including:

Shafts: Shafts are cylindrical parts that are used to transmit power.

Bushings: Bushings are cylindrical sleeves that are used to reduce friction and wear.

Gears: Gears are used to transmit rotational motion from one shaft to another.

Bearings: Bearings are used to support rotating shafts and reduce friction.

How to Programme a CNC Lathe?

Programming a CNC lathe involves creating a set of instructions that tell the machine how to move the cutting tools and how to control the speed of the spindle. The instructions are written in a special language called G-code.

There are two main ways to program a CNC lathe:

- Manual programming: In manual programming, the operator writes the G-code instructions by hand. This method is time-consuming and error-prone.

- CAM programming: In CAM programming, the operator uses a computer-aided manufacturing (CAM) software program to create the G-code instructions. The CAM software uses a 3D model of the part to generate the instructions. This method is faster and more accurate than manual programming.

Once the G-code instructions have been created, they are loaded into the CNC lathe’s computer.

The computer then executes the instructions, and the machine moves the cutting tools and controls the speed of the spindle to machine the part.

You have questions? We have the answers.

Reach out to us if you need more information about CNC Lathe Machine. We are happy to serve you.