Tandem CNC Press Brake

Heavy Duty Hybrid CNC Press Brake

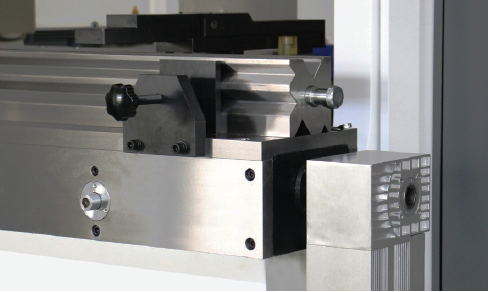

Press Brake Machine

- Dual servo oil-electric hybrid system for powerful energy efficiency and reliable operation

- Accurate Linear Scale with 0.005mm precision for synchronized Y1-Y2 axis operation

- High-quality, precision-ground tooling made for durability and long lifespan (customizable)

- Back Gauge System with high speed, accuracy, and extended positioning range, powered by servo-motor

- Structured for safety and stability with a standard 3+1 axis configuration: Y1-Y2 axis (main cylinder movement), X axis (backgauge adjustment), W axis (mechanical compensation table)

- Equipped with Swiss CYBELEC CybTouch 12PS:

- 12″ color touch screen display (800*600 resolution)

- Intuitive full-touch interface with automatic functions for easy operation

- Clear display and easy-to-touch large buttons

- Automatic calculations for bending angle, main pressure, and deflection compensation

- Bending sequence and product angle storage

- Finger-drawable sectional view of the workpiece