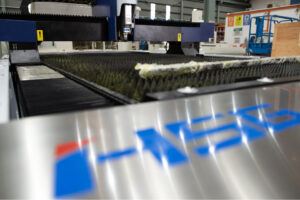

The world of steel fabrication is constantly evolving. At the heart of this groundbreaking shift, laser metal cutting machine have emerged as transformative tools. But, among lasers, two names predominantly rise to the top – Fiber Lasers and CO2 Lasers. So, amidst this technological sea change, how do these two compare, and which is more suited for steel fabrication? Let’s journey through their details and see for ourselves.

Peeling Back the Basics: Fiber vs. CO2 Laser Metal Cutting Machine

What are Fiber and CO2 Lasers?

To kick things off, let’s talk about what Fiber and CO2 lasers are. Fiber Laser Metal Cutting Machine are essentially solid-state lasers, employing optical fibers rich with rare-earth elements like ytterbium or neodymium. This innovative composition amplifies light, giving birth to a laser beam that’s perfect for precise cutting.

In contrast, CO2 Lasers work a little differently. They harness a gas mix, sprinkled with elements like carbon dioxide and helium. Introducing electricity to this concoction causes it to shine with infrared light. This light, once amplified, is poised and ready for cutting.

Evaluating Performance and Efficiency

Efficiency Differences

In the arena of energy efficiency, fiber laser metal cutting machine truly shine. Boasting an efficiency rate of about 70-80%, they easily outpace CO2 lasers, which linger at a modest 10-20%. Simply put, when energy consumption takes center stage, fiber laser metal cutting machine are the clear winners, promising tangible cost reductions over time.

Delving into Cutting Speed and Precision of the Laser Metal Cutting Machine

Speed Comparisons

Switching gears to discuss cutting speed, fiber laser steel cutting machine, especially when working with thinner materials, demonstrate a clear advantage. They race through materials like stainless steel, almost twice as swiftly as their CO2 counterparts. This swiftness becomes a massive advantage in high-volume production environments.

Precision Levels

Precision-wise, it’s a close call. Both laser metal cutting machine are incredibly accurate, but fiber lasers, with their tinier focal diameter, edge ahead. They are masters at delivering delicate cuts and intricate engravings, making them the go-to for detailed tasks.

Diving into Material Versatility

Here, CO2 lasers gain some ground. They’re not just adept at cutting metals but are also remarkably proficient with non-metals like wood and acrylic. For industries juggling diverse materials, this adaptability of CO2 laser metal cutting machine can be the deciding factor.

Maintenance and Longevity

Maintenance Needs and Durability Aspects

Transitioning to maintenance, fiber lasers steal the limelight again. With a simpler design and fewer parts to worry about, they stand out as robust and long-lasting. On the flip side, CO2 lasers, with their complex design, might keep you on your toes with more regular maintenance.

Weighing Operational Costs of Laser Metal Cutting Machine

Initial Investments vs. Long-term Savings

Although the initial price tag on fiber lasers may induce a gasp, they redeem themselves with their operational costs. The combined allure of heightened efficiency and reduced upkeep makes them a more cost-effective choice in the long haul.

Safety and Eco-friendliness

Invest in a machine that promises to stick around. Durable and robust construction means fewer headaches down the road.

Conclusion

To wrap things up, the choice between fiber and CO2 lasers isn’t black and white. For those prioritizing efficiency, speed, and precision, fiber lasers seem like a natural fit, especially in steel fabrication. Yet, if material versatility is the order of the day, CO2 lasers have their merits.

In our dynamic world of steel fabrication, staying informed is key. As we embrace the future, a deep understanding of these powerful tools is paramount for success.

FAQs

Are fiber laser metal cutting machine more expensive than CO2 laser metal cutting machine?

While the initial investment might be higher for fiber lasers, they typically result in cost savings in the long run due to efficiency and lower maintenance.

Can CO2 laser metal cutting machine cut non-metallic materials?

Yes, CO2 lasers are adept at cutting materials like acrylic, wood, and glass.

Which laser is faster for cutting thin metals?

Fiber lasers generally cut up to twice as fast as CO2 lasers, especially for thin materials like stainless steel and aluminum.

Do fiber laser metal cutting machine have a smaller carbon footprint?

Yes, due to their higher efficiency, fiber lasers typically have a smaller environmental impact than CO2 lasers.

Are fiber lasers safer than CO2 laser metal cutting machine?

Fiber lasers emit a beam that’s absorbed by the human body, making them generally considered safer than CO2 lasers.